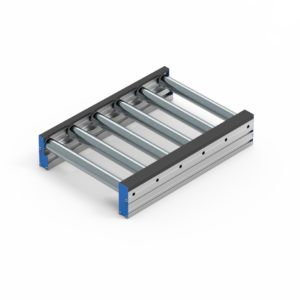

Roller conveyor have major benefits of transporting cargos:

- highly efficient in moving heavy loads from one place to another

- Handling of a wide variety of materials, including boxes, crates, and pallets.

- Because of their design they are easy to maintain.

- designed to fit into small spaces

- designed for specific needs, including speed, load capacity, and conveyor length.

Roller conveyors can be used in many areas such as warehouse and production. Roller conveyors can be designed with curves or transverse modules, positioning units, etc. Additional modules are built in to perform various operations such as moving pallets between lines or positioning pallets to required tolerances for correct work process.

In our program we offer :

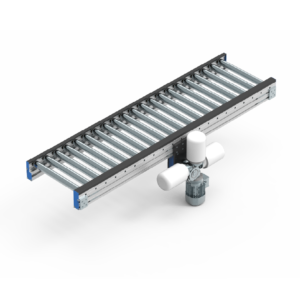

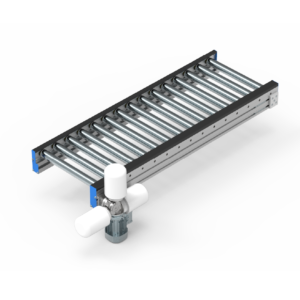

– Driven roller track – heavy drive 17RDMH,

– Driven roller track – light drive 17RDML,

– Driven roller track with electric roller 17RDMM,

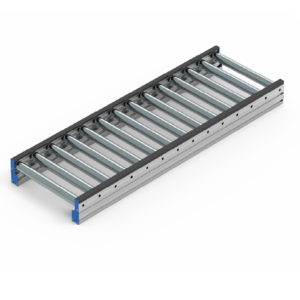

– Non-driven roller track 17RTR.

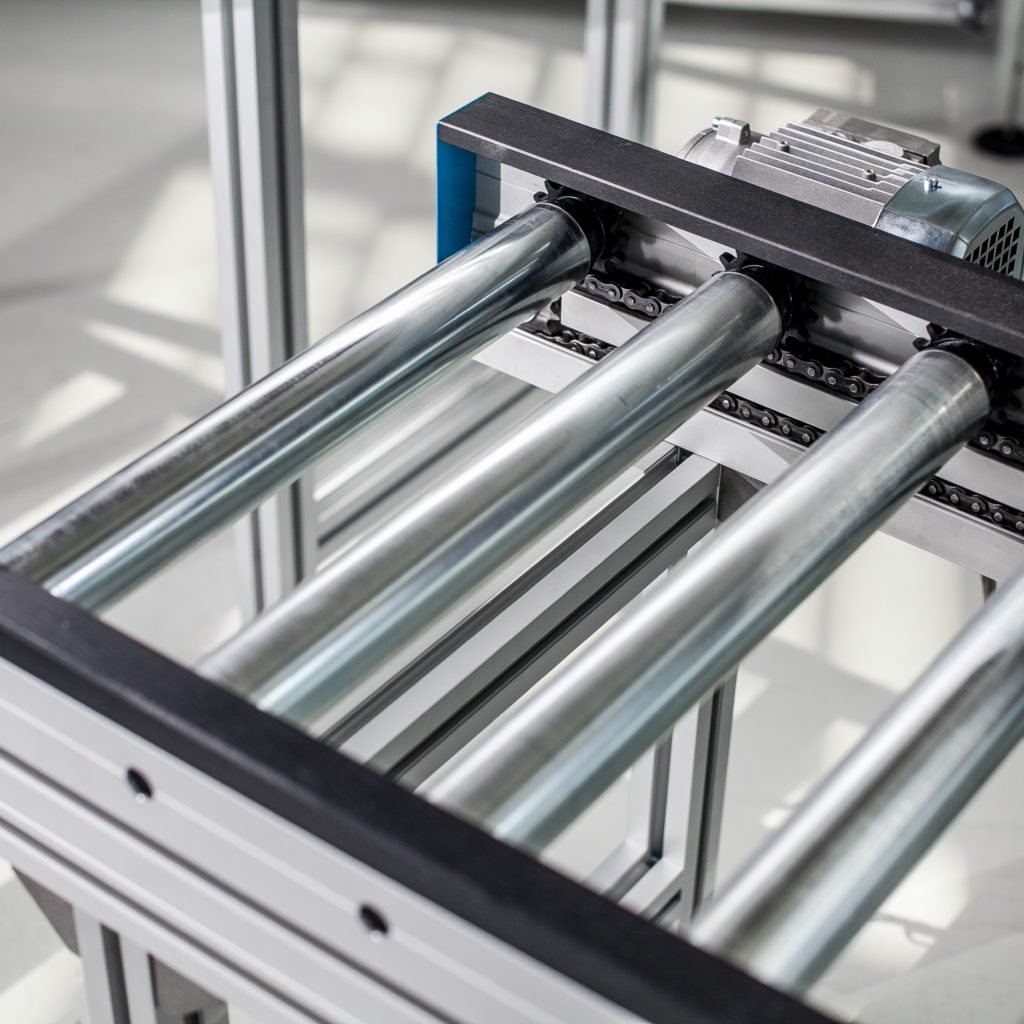

Driven Roller conveyors 17RDMH , 17RDML and 17RDMM work as driven roller conveyor, they differ in the type of drive unit:

- 17RDMH is designed for larger pallets and higher weights and can transport up to 2000 kg on total length. The main advantage between 17RDML and 17RDMH is that 17RDMH can work in both directions due to position of drive unit.

- 17RDML is designed for pallets with a lower weights and can transport up to 1000kg on total length. A great option when shorter tracks are required as lighter versions cost less.

- 17RDMM driven roller conveyor is equipped with 24V roller motor. This system has many advantages as it can be used in many areas where there is not enough space to implement other roller conveyor options. since there is no engine attached to the sides. Because it uses a 24V motor, it can be implemented in AGVs or other robotic systems.

The non-driven roller track 17RTR operates solely on gravity, which means that a difference in height between the starting and ending point of the roller track is required for automatic movement of the cargo.