Conveyor systems form the backbone of material handling in diverse industries, and the choice of conveyor design is critical in optimizing workflow. This article delves into the characteristics, advantages, and customization options of straight conveyors, L-shaped conveyors, and the unique Z-shaped conveyors, which incorporate an additional straight section on the second elevation.

STRAIGHT CONVEYOR:

Usability:

Straight conveyors provide a direct and linear solution for the efficient movement of materials from one point to another. Their uncomplicated design makes them suitable for applications requiring continuous and uninterrupted material flow.

Advantages:

- Simplicity and reliability: The straightforward design of straight conveyors contributes to easy installation and maintenance, ensuring consistent and reliable operation.

- Ideal for Long Distances: Straight conveyors are particularly well-suited for applications where materials need to be transported over extended distances without significant elevation changes.

Customization for specific requirements:

Straight conveyors can be customized based on length, material, and drive position to meet the unique needs of various industries.

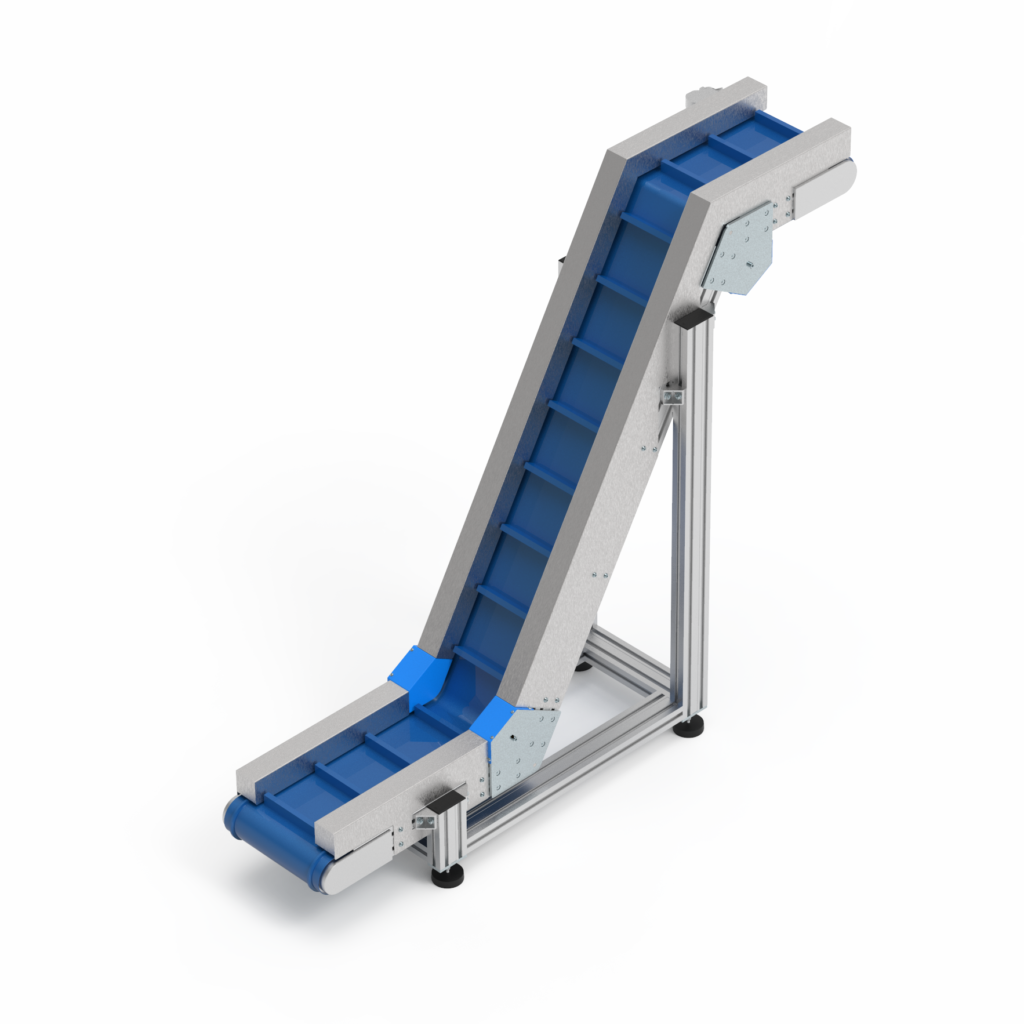

L-SHAPED CONVEYORS:

Usability:

L-shaped conveyors, created by combining one straight and one inclined conveyor tracks with different heights, introduce versatility to material handling. One section remains straight, while the other features an inclined or declined track, allowing for the transport of materials at two distinct elevation levels.

Advantages:

- DUAL ELEVATION LEVELS: L-shaped conveyors enable simultaneous material transport at two different heights, making them ideal for applications when cargo has to be transporter from lower to higher hight.

- SPACE OPTIMIZATION: The dual-height design efficiently utilizes vertical space, making L-shaped conveyors valuable in small spaces.

- FLEXIBLE MATERIAL FLOW: The angled section of the L-shaped conveyor provides flexibility in directing materials.

Customization for specific requirements:

L-shaped conveyors can be customized to meet specific incline or decline angles, offering tailored solutions based on the unique material handling needs of different industries.

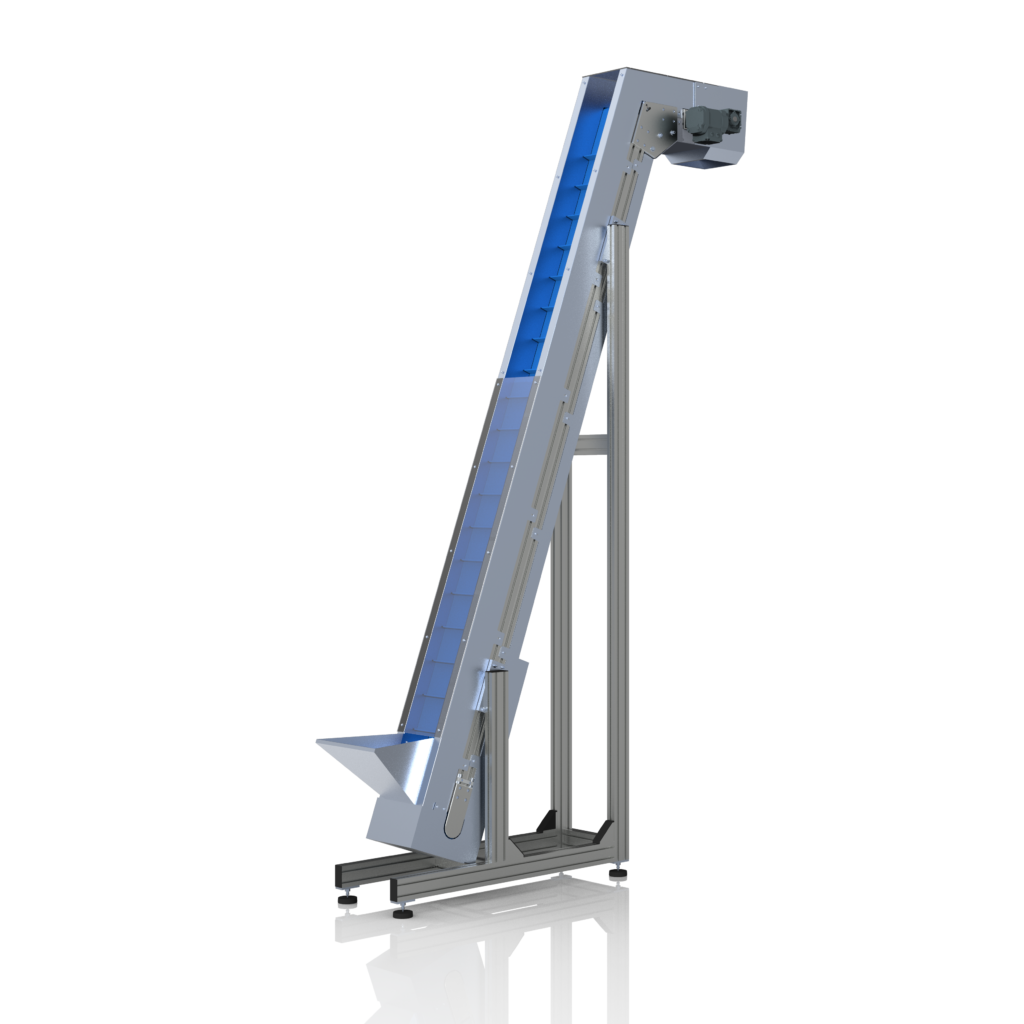

Z-SHAPED CONVEYORS:

Usability:

Z-shaped conveyors, an extension of L-shaped designs, incorporate an additional straight section on the second elevation. This configuration allows for a more intricate material flow, particularly suitable for applications where materials need to traverse multiple height levels with straight sections.

Advantages:

- Enhanced Versatility: The addition of a straight section on the second elevation provides enhanced versatility, accommodating diverse material flow requirements.

- Complex Material Paths: Z-shaped conveyors excel in applications where materials must navigate intricate paths involving both elevation changes and straight sections.

Customization for specific requirements:

Z-shaped conveyors, like L-shaped ones, can be customized to meet specific incline or decline angles and straight section lengths, ensuring a tailored solution that aligns precisely with operational needs.

In our specialized program, all three conveyor types—straight, L-shaped, and Z-shaped—can be precisely tailored to meet the specific requirements of our customers. This customization ensures that the conveyor systems align perfectly with the operational needs of the facility, whether optimizing for linear transport or accommodating dual-height and complex material flow.

In conclusion, the choice between straight, L-shaped, and Z-shaped conveyors depends on the specific material handling requirements of a given industry.

While straight conveyors excel in linear transport, L-shaped conveyors add versatility with dual-height material flow, and Z-shaped conveyors further enhance versatility by incorporating an additional straight section. Understanding these design distinctions allows businesses to make informed decisions, selecting the conveyor system that maximize their material handling efficiency.